Surgeons are constructing the customisable composite fixation plate AdhFix

The BoneFix project builds on light-cured on-site customisable implant innovations that have the potential to improve the surgical outcome in bone fracture or restoration surgeries. Within the project Biomedical Bonding’s Bonevolent™ AdhFix is used as the first fixator plate made in surgery from a light-cured composite, to enable patient-specific plates contoured for each individual fracture.

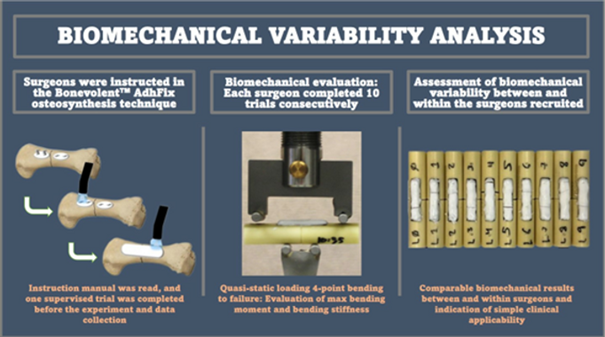

For a fracture fixator implant, mechanical durability is of major importance and a customisable implant must meet the required load-bearing capacity each time. Thus, it is critical that the method of creating an AdhFix plate is easy to learn and reliably provides plates that perform as intended. Here, a study conducted in the BoneFix project led by surgeons from Region H in Copenhagen and biomechanical researchers at AO Research Institute in Davos assesses the inter- and intra-surgeon biomechanical variability and usability of the AdhFix osteosynthesis platform. Six surgeons, ranging from specialists to novices, conducted ten osteosyntheses each with AdhFix on a synthetic bone fracture model and the mechanical performance, implant size and time to complete the fixation were analysed. The on-site sculpturing and light-curing concept were no match for the surgeons, making plates with consistent biomechanical stability and only slight variations were noted in between surgeons.

“This was a very interesting study to perform, since the investigation of variability in relation to biomechanical properties is not very common in this field of science. However, with novel customizable fracture fixation techniques, these types of analyses are becoming increasingly relevant”, says Thomas Colding-Rasmussen, orthopaedic surgeon at Region H. Read more about the study and results at: https://www.mdpi.com/2306-5354/10/10/1146