Siemens Healthineers’s new £250m Oxford facility to be UK’s first major production site for new MRI DryCool technology

Siemens Healthineers has announced a new £250 million facility in North Oxfordshire that will design and manufacture superconducting magnets for advanced MRI scanners used in healthcare facilities globally. The site will be home to novel technology that minimizes the use of helium, making the MRI scanners lighter, easier to install and more sustainable.

Siemens Healthineers’s new £250m Oxford facility

Construction has begun on the 56,000m2 site, which will support more than 1,300 skilled jobs. It will be the UK’s first major production site for the new so-called DryCool technology by Siemens Healthineers, which reduces the amount of helium required in an MRI scanner from 1,500 litres to under a single litre. The new facility, which will be operationally carbon-neutral, will provide a range of financial, infrastructure and environmental benefits to the local economy from its planned opening in 2026, underlining the company’s decades-long commitment to manufacturing in the Oxford area.

Research and development hub

With high-end manufacturing automation technology in place, Siemens Healthineers will provide vital additional capacity to help satisfy rising global demand for MRI products. The new factory will include a research and development hub responsible for new technologies such as designing and manufacturing some of the world’s smallest and most lightweight whole-body scanners.

Siemens Healthineers investing in the UK

As one of six current and planned Siemens Healthineers manufacturing sites in the UK, the new facility underscores the company’s significant high-tech footprint across the country. The new site is set to support over 1,300 jobs when fully operational, including the retention of over 600 Oxfordshire-based jobs currently at an existing Siemens Healthineers facility in Eynsham. Many of the roles are for highly skilled workers such as physicists, engineers, technicians and specialized support staff. These are in addition to workers who will be employed during the site’s construction. The phased transition is estimated to be completed by 2030, subject to variable demand for the products developed at the site.

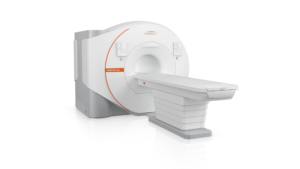

Siemens Healthineers-Magnetom Flow MRI with new cooling technology

Global centre for low-helium magnet technology

“MRI technology plays a vital role in diagnosing disease, helping patients to get healthy and stay healthy. As a world leader in medical imaging, we are very proud to open the next chapter of our history here in Oxford,” said Bernd Montag, chief executive of Siemens Healthineers. “This factory will be the global centre for our innovative low-helium magnet technology, meaning we consume far less of a scarce natural resource and enable access to MRIs for many more patients.”

With support from developer Tritax Symmetry, the building is designed to be carbon-neutral in operation, with careful consideration for the community and environment, and strategies aimed at reducing energy demand and increasing health and wellbeing.