Newly established Orion Medical enables advanced 3D printing for precision medicine

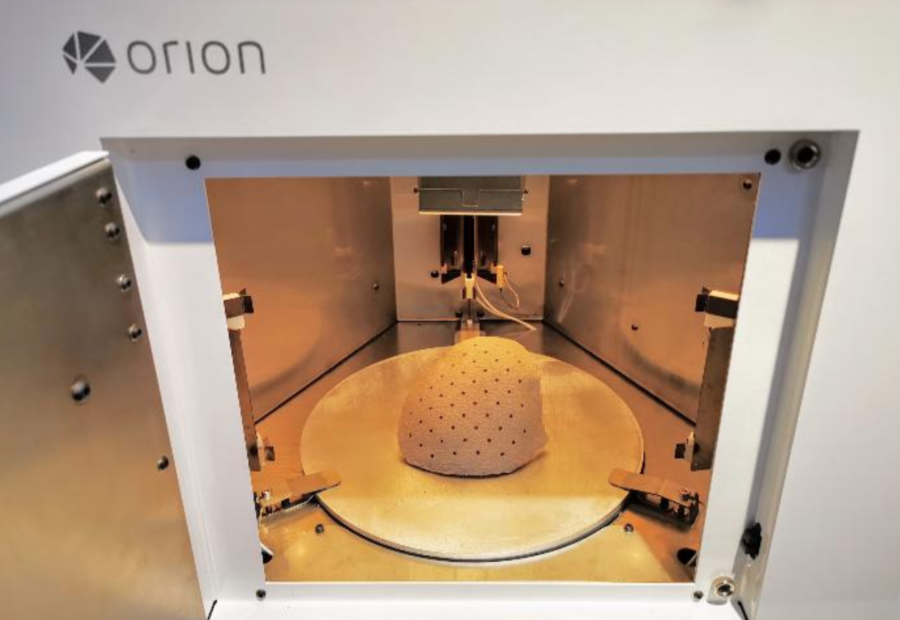

Founded in March this year, Orion Medical, based in Cham, Switzerland, has been established as a specialist in 3D printing for the medical devices industry. The company is closely linked to Orion Additive Manufacturing (Orion AM), an established manufacturer of 3D printing systems for high-performance polymers based in Berlin, Germany.

The key advantage of Orion Medical’s additive manufacturing technology is its Thermal Radiation Heating (TRH) system, which enables the 3D printing of customized medical devices on demand with injection moulded strength and 100% density.

In preparation for use its technology in the medical field, Orion Medical’s founding team engaged in an 18-month-long preparation period for the MedTech qualification of Orion AM’s technology prior to founding the company.

3D printing for Medtech

To make TRH technology available to the MedTech industry and enable medical industry players – hospitals, point-of-care centres, MedTech suppliers – to participate in the growing market segment of precision medicine, Orion’s technology has been adapted to MedTech and regulatory requirements. This includes the conversion of the print chamber as well as the conversion of all support systems of the 3D printer according to aspects and requirements of relevant regulations, standards, and norms.

As a manufacturer of 3D printing systems for the medical industry, Orion Medical GmbH observes the specifications of ISO 13485 as well as the requirements stipulated in MDR (EU) 2017/745 for the manufacturing of medical devices.

Thermal Radiation Heating

Extrusion-based printing technologies like Fused Filament Fabrication (FFF) typically suffer from weak bonding between layers, delamination, and deformation as the material cools after deposition. Orion’s proprietary technology applies continuous TRH to the part during 3D printing to effectively bond the printed layers together, resulting in injection moulded strength and 100% density. This makes Orion Medical’s solution extremely competitive with injection moulding and CNC machining to produce personalized medical devices on demand.

Orion Medical’s M-Series additive manufacturing systems use this technology to enhance the properties of medical-grade polymers such as Polyether ether ketone (PEEK) and Polyphenylsulfone (PPSU), enabling best-in-class results in functional end-use parts in medical device applications, including load-bearing implants.

Bio-compatible, X-ray-friendly polymers like PEEK are commonly used to replace titanium implants. 3D printing with these materials is opening the door to a new world of patient-specific implants that can be highly customized to each patient’s needs.

“With thermal radiation, the heat penetrates the material so that the layers really fuse together. The result is parts with more uniform strength, higher density, and stability. Orion’s technology solves the anisotropic nature of FFF 3D printing, even for difficult-to-print aerospace materials like PEEK and PEI. This results in fully isotropic properties,” explains Christoph Koslowski, managing partner, Orion Medical.

Quality management system

To act as a qualified supplier for its customers according to ISO 13485:2016 and MDR, Orion Medical follows the requirements for a QM system as demanded by MDR 2017/745 in Article 10. Orion Medical is always thus a reliable partner in the highly regulated environment of medical technology. The strength of Orion Medical’s solutions lays in its ability to cover the entire value chain from medical-grade materials and additive manufacturing systems to surface-functionalization of implants and regulatory services.

Accompanying services

Orion Medical offers its customers and all parties interested in 3D printing of medical devices additional services besides the medical printers of the M-Series. These include design support, design transfer of implant concepts for 3D printing, but also regulatory assistance such as compiling of product files, advice in terms of ISO 13485:2016 and the MDR (EU) 2017/745, specifically advice regarding Article 5a of the MDR (EU) 2017/745: Placing on the market and putting into use – manufacture AND use in healthcare facilities.

For more information, visit: http://www.orion-am.com/