Worm-inspired 3D printing breakthrough paves way for next-gen medical implants

Researchers at the University of Colorado Boulder and the University of Pennsylvania have developed a novel 3D printing technique that produces elastic, tough, and shapeable materials with potential applications in cardiac and cartilage repair.

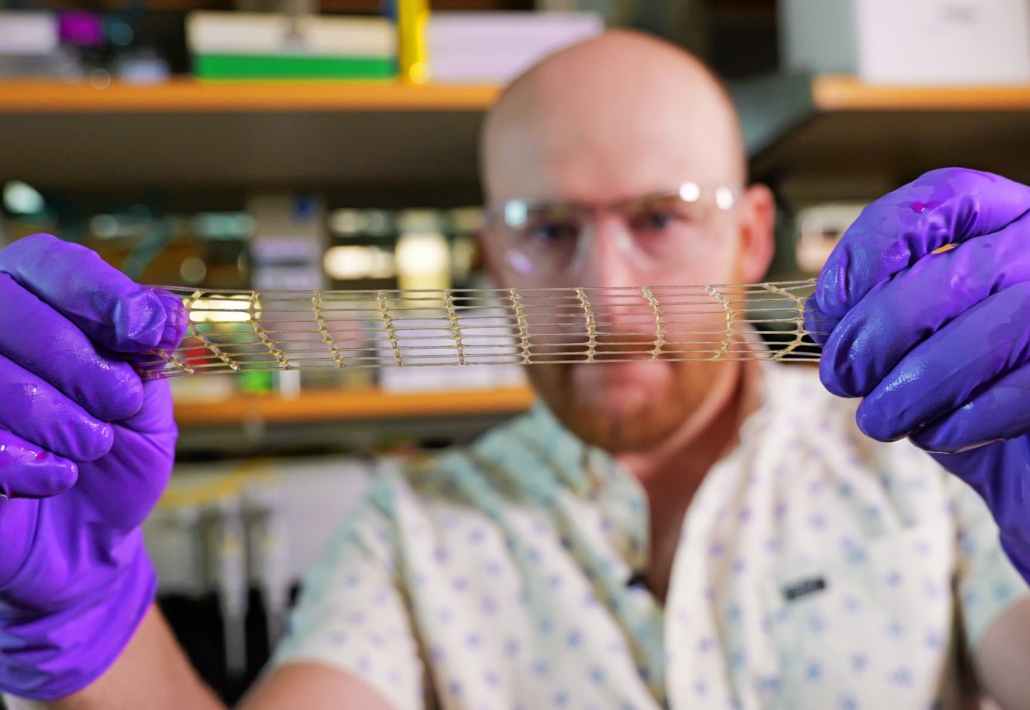

Professor Jason Burdick demonstrates the elasticity of the new 3D-printed material.

A team of scientists from the University of Colorado Boulder and the University of Pennsylvania has made a significant advancement in the field of biomaterials. Their innovative 3D printing method, known as CLEAR (Continuous-curing after Light Exposure Aided by Redox initiation), allows for the creation of materials that combine strength, elasticity, and adaptability – qualities that are crucial for replicating the complex nature of human tissues. Their research is published in Science [1].

The challenge of mimicking natural tissue

Human tissues present a unique challenge for biomedical engineers. They are simultaneously strong and flexible, capable of withstanding significant stress whilst maintaining their shape and function. Previous attempts at creating artificial tissues have often fallen short, producing materials that were either too brittle or too rigid to effectively mimic natural tissue behaviour.

Professor Jason Burdick, the senior author of the study and a professor of chemical and biological engineering at CU Boulder’s BioFrontiers Institute, explained the significance of their work: “Cardiac and cartilage tissues are similar in that they have very limited capacity to repair themselves. When they’re damaged, there is no turning back. By developing new, more resilient materials to enhance that repair process, we can have a big impact on patients.”

The CLEAR technique: Inspired by nature

The researchers drew inspiration from an unlikely source: worm ‘blobs’. These tangled masses of worms exhibit both solid and liquid-like properties, a characteristic the team sought to replicate in their biomaterials.

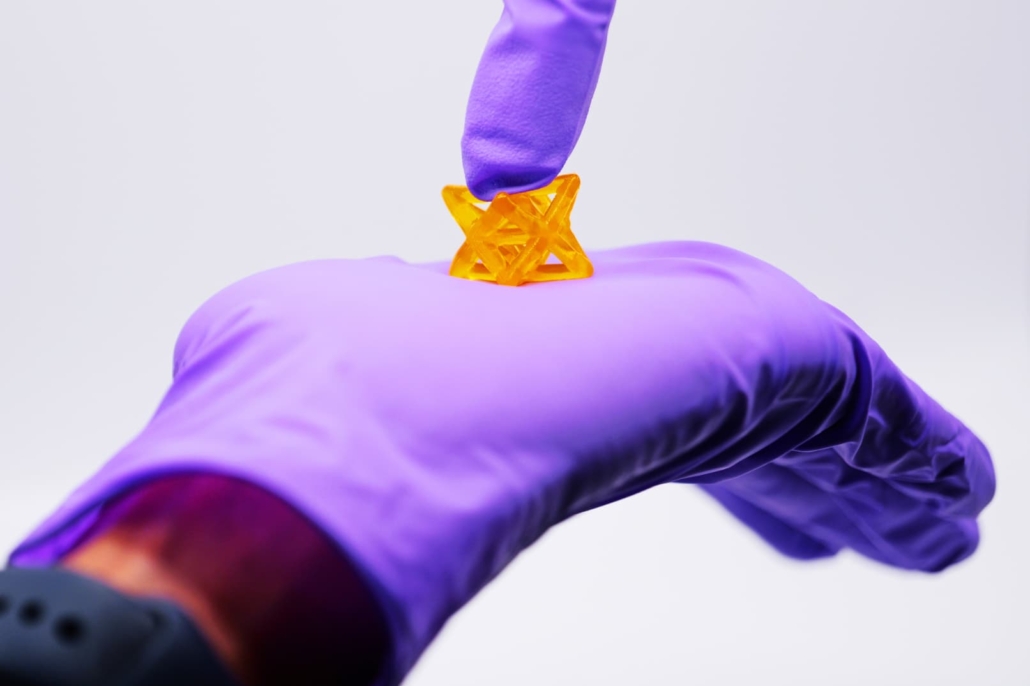

The CLEAR method involves a series of steps that create entanglements of long molecules within the 3D-printed material, similar to the intertwined nature of worm blobs. This process results in materials that are significantly tougher than those produced by standard 3D printing techniques such as Digital Light Processing (DLP).

Unprecedented strength and adaptability

When subjected to rigorous testing, including stretching and weight-loading, the materials demonstrated remarkable resilience. In one particularly striking test, a researcher even ran over a sample with her bicycle, highlighting the material’s durability.

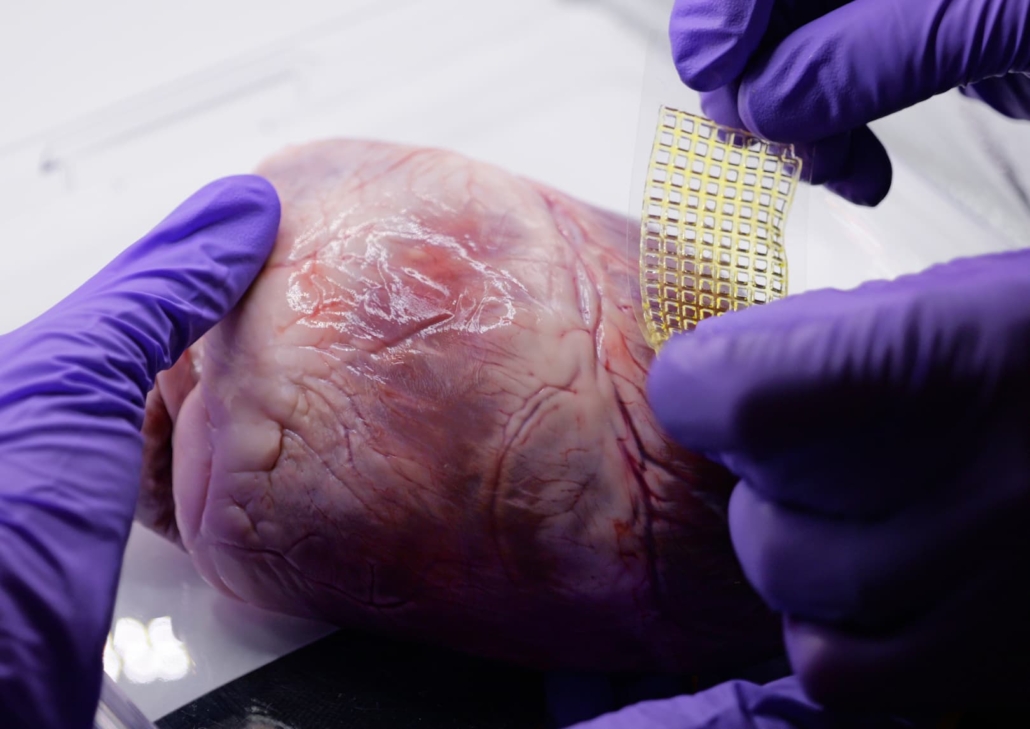

Crucially, these new materials also showed an ability to conform and adhere to animal tissues and organs, a property that has eluded researchers in the past. Matt Davidson, a research associate in the Burdick Lab and co-first author of the study, emphasised this achievement: “We can now 3D print adhesive materials that are strong enough to mechanically support tissue. We have never been able to do that before.”

Potential applications in medicine

The potential applications for this technology in medicine are vast. Prof. Burdick envisions a future where these 3D-printed materials could be used to repair heart defects, deliver tissue-regenerating drugs directly to organs, create cartilage patches, or even replace traditional sutures with a needle-free alternative that causes less tissue damage.

The team has already filed for a provisional patent and plans to conduct further studies to better understand how tissues react to these materials.

Environmental benefits

Beyond its medical applications, the CLEAR technique offers environmental advantages over traditional 3D printing methods. It eliminates the need for additional energy to cure or harden parts, making the printing process more eco-friendly.

Abhishek Dhand, the first author of the study and a doctoral candidate at the University of Pennsylvania, highlighted the broader implications of their work: “This is a simple 3D processing method that people could ultimately use in their own academic labs as well as in industry to improve the mechanical properties of materials for a wide variety of applications. It solves a big problem for 3D printing.”

Future outlook

While the research is still in its early stages, the potential impact on patient care and medical technology is significant. As the team moves forward with additional studies and refines their technique, we may see a new generation of biomaterials that more closely mimic the complexity and resilience of natural human tissues.

This breakthrough represents a significant step forward in the field of regenerative medicine and tissue engineering. As research progresses, it could lead to more effective treatments for a wide range of conditions, particularly those involving cardiac and cartilage tissues, which have limited natural repair capabilities.

Reference:

- Dhand, A., Davidson, M. J., & Burdick, J. A. (2024). Additive manufacturing of highly entangled polymer networks. Science. https://doi.org/10.1126/science.adn6925