Biopolymer mitralheart valve feasibility study provides hope for mitral disease patients

The first-in-human use of Foldax’s biopolymer Tria™ heart valve as a replacement for a diseased mitral valve has shown positive results. The first case was performed by David Heimansohn, MD, at Ascension St. Vincent Hospital, Indianapolis, as part of a U.S. early feasibility research study.

Foldax intends to revolutionize the heart valve replacement market by largely solving the durability, quality of life and manufacturing issues that have vexed the clinical community and industry for decades.

“We are excited to be the first centre in the world to implant the innovative Tria mitral valve as part of this research study. In this first-in-human procedure, we saw an immediate improvement in the functionality of this patient’s heart valve once the valve was in place,” said Dr. Heimansohn. “Since it has been designed to be a more durable artificial valve that may not require lifetime anti-coagulation therapy, it is hoped that Tria will be proven effective through this research study for patients with mitral disease, who are often much younger than patients with other valvular diseases.”

Commenting on the successful pilot study, Frank Maguire, Foldax CEO, said: “This milestone continues to build upon the clinical evidence supporting Foldax’s Tria valves, which includes the ongoing Tria aortic valve study encompassing several patients who have celebrated one year with their implants and are doing well. Our transcatheter aortic valve replacement (TAVR) continues its rapid development path and will give us both surgical and transcatheter approaches in our family of heart valves.

“Foldax intends to revolutionize the heart valve replacement market by largely solving the durability, quality of life and manufacturing issues that have vexed the clinical community and industry for decades,” Maguire added.

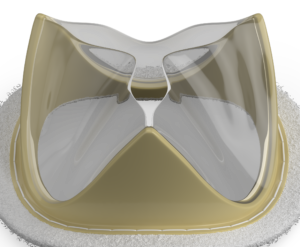

The Tria valves reimagine the heart valve by incorporating a new, proprietary biopolymer – LifePolymer™ – with innovative valve designs intended to resist calcification, withstand stresses and strains without failure, and restore patient quality of life without lifelong use of anticoagulants.

Tria is also the first and only heart valve to be robotically produced, which is possible due to its polymer leaflets that can be consistently manufactured with precise thicknesses and are designed to achieve a valve with predictable performance that lasts a lifetime.